Surface heating

What are water-based heating and cooling systems?

Water-based heating and cooling systems for walls and ceilings are pipes or pipe registers plastered in clay mortar. Due to the larger heat dissipation surface, a lower surface temperature is required to heat the rooms compared to conventional convection radiators. This has a significant impact on efficiency, especially when heat is generated by a heat pump. The emission of heat via a large surface and radiation is not only healthy and pleasant, but also saves energy, as the room temperature can remain lower with a high proportion of radiant heat than when heating with heated air, as is usual with convection radiators. In addition, the surface systems can easily be switched to cooling in summer by circulating cold water through the pipes.

Water-based heating and cooling systems

Endless pipe systems

With endless pipe systems, pipe clip rails are first attached to the substrate. The pipes are then simply pressed into the appropriate clamps and secured. The pipe spacing can be varied depending on the heat requirement, changes in the direction of installation and other reactions to site conditions are easily possible.

Image: VIEGA

Advantages

– Inexpensive, clip rails and pipes are available in simple quantities.

– High flexibility in terms of heat output, adaptable even for surfaces that are difficult to cover and different thermal requirements

Disadvantages

– More complex to install than ready-made pipe registers

Technical data

Pipe materials: Aluminum-plastic composite or plastic

Outside diameter*: 8, 12, 14 or 16 mm

* Larger cross-sections may need to be considered for the supply lines

Total thickness of clay plaster structure: 18 to 26 mm depending on the pipe

Output: 50 to max. 200 W/m2 *

* Output depends on pipe laying distance, flow temperature, flow/return spread, room temperature

ClayTec clay plaster mortar

Plastering pipes: Clay undercoat plaster straw or clay plaster mineral

Reinforcement: Flax fabric or glass fabric

Finish: YOSIMA clay designer plaster or

Clay topcoat plaster fine 06 and Primer WHITE and CLAYFIX clay paint or clay topcoat plaster fine 06 and clay paint ready to use

Application of clay plaster

The substrate must have sufficient grip; in case of doubt, the grip should be established with DIE ROTE primer or a comb filler made from clay adhesive and reinforcing mortar or a suitable building adhesive. The undercoat plaster is applied up to the pipe crowns, over which the plaster is applied. Depending on the clay plaster mortar and pipe diameter, several layers may need to be applied. Thick layers of plaster must be able to dry quickly; if necessary, drying must be accelerated using suitable equipment. Starting up the heating also shortens the drying time. After the base coat has dried, a second layer of the same mortar as before is applied to a thickness of approx. 5 mm above the pipe crown. The reinforcing mesh is worked into this still wet layer; the sheets must be installed with an overlap of at least 100 mm; the mesh must be generously extended onto unheated plaster areas. After the reinforcement layer has dried, apply the clay finish of your choice.

Water-based heating and cooling systems

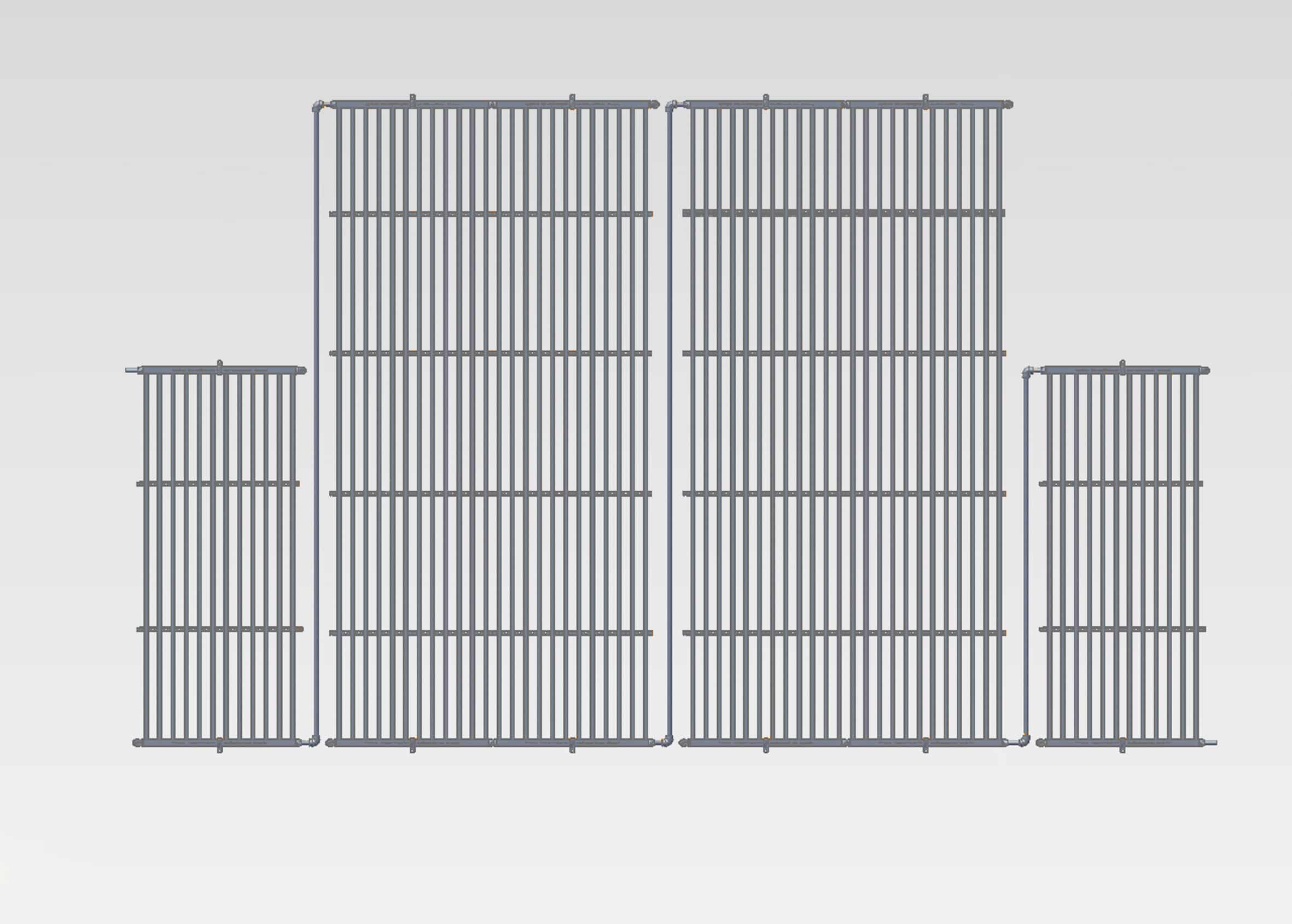

Pipe register systems

In these systems, the pipes are joined together to form finished modules that are attached directly to the substrate. The registers are coupled using pipe connectors and then simply connected.

Image: AQUATHERM

Advantages

– Quick installation

– Simple heating dimensioning, as defined heat output per module

Disadvantages

– Less flexibility

Technical data

Pipe materials: copper, aluminum or plastic

Outer tube diameter*: 2.5 x 8, 4.5 mm (thin pipe systems), 8, 10, 12, 14 mm

* Larger cross-sections may need to be considered for the supply lines

Total thickness of clay plaster structure: 10 to 24 mm depending on the system/pipe

Output: 50 to max. 230 W/m2 *

* Power depends on pipe material, flow temperature, flow/return spread, room temperature

ClayTec clay plaster mortar

Plastering pipes: SanReMo clay plaster (thin pipe systems), straw clay undercoat plaster or mineral clay plaster

Reinforcement: Flax fabric or glass fabric

Finish: YOSIMA clay designer plaster or

Clay topcoat plaster fine 06 and primer WHITE and CLAYFIX clay paint or clay topcoat plaster fine 06 and clay paint ready to use

Application of clay plaster

The substrate must have sufficient grip; in case of doubt, the grip should be established with primer RED or a comb filler made from clay adhesive and reinforcing mortar or a suitable building adhesive. The undercoat plaster is applied up to the pipe crowns, over which the plaster is applied. Depending on the clay plaster mortar and pipe diameter, it may be necessary to work in several layers. Any thick layers of plaster must be able to dry quickly; if necessary, drying must be accelerated using suitable equipment. Starting up the heating also shortens the drying time. After the base coat has dried, a second layer of the same mortar as before is applied to a thickness of approx. 5 mm above the pipe crown. The reinforcing mesh is worked into this still wet layer; the sheets must be installed with an overlap of at least 100 mm; the mesh must be generously extended onto unheated plaster areas. After the reinforcement layer has dried, apply the clay finish of your choice.

Water-based heating and cooling systems

Pipe register systems on building boards

Pipe registers are offered in combination with various construction panels, with the pipes lying in milled pipe channels. The boards can make installation easier and usually also have an insulating function, e.g. to achieve thermal decoupling of the surface heating from solid building components. Thicker boards can take on the function of internal insulation in whole or in part.

Picture: WAKA

Advantages

– Quick installation

– Heating and insulation in one product.

Disadvantages

– Less flexibility

– Greater thickness

Technical data

Pipe materials: copper, aluminum-plastic composite or plastic

Board thickness: 25 mm, 40 mm (interior insulation board)

Thickness of clay plaster structure on the panel: 5-10 mm

Output: 50 to max. 150 W/m2 *

* Output depends on flow temperature, flow/return spread, room temperature

Water-based heating and cooling systems

Precast element systems

With these special construction boards, the heating pipe is already completely encased in clay. The heating panels are delivered to the construction site as precast elements and only need to be fixed, coupled together and connected. The clay plaster coating is applied in thin layers.

Picture: WEM

Advantages

– Fast installation

– Dry construction technique with little plastering work and drying time

Disadvantages

– Less flexibility

– More expensive than other systems

Technical data

Pipe materials: Aluminum-plastic composite

Panel thickness: 25 mm

Thickness of clay plaster structure on the panel: 5 mm

Output: 80 to max. 170 W/m2 *

* Output depends on flow temperature, flow/return spread, room temperature

ClayTec clay plaster mortar

Reinforcement layer: Clay adhesive and reinforcement mortar, flax fabric or glass fabric

Finish: YOSIMA clay designer plaster or

Clay topcoat plaster fine 06 andprimer WHITE and CLAYFIX clay paint or

Clay topcoat plaster fine 06 and clay paint ready to use

Clay plaster finish

Clay adhesive and reinforcing mortar is applied to a thickness of 3 mm. The reinforcing mesh is worked into this still wet layer, the sheets must be installed with at least 100 mm overlap, the mesh must be generously continued on unheated plaster areas. After the reinforcement layer has dried, apply the clay finish of your choice.

Electric based heating systems

Electric based heating systems

In these systems, both heat production and heat radiation take place via carbon-containing grids, perforated mats or fleeces to which an electrical voltage is applied. The heating media are bonded to the substrate with clay adhesive and reinforcing mortar and worked in.

Image: Mfh systems

Advantages

The investment in equipment is extremely low. You don’t need boilers, pumps or piping systems. The construction effort is also minimal; instead of pipes for the flow and return, only power cables are required. As with all surface heating systems, there are no radiators. In difficult situations, electric-based heating systems are often sought after problem solvers.

Disadvantages

If electric heating is the sole heating system, the energy costs are often still too uneconomical. In these cases, the building should at least be very well insulated (see also the relevant requirements of the Building Energy Act (GEG)). If the building generates its own electricity, this aspect can be put into perspective.

Technical data

Materials: Carbon laminated, with paper, as fleece or mesh fabric

Thickness of clay plaster structure: 5 mm

Output: 60 to 220 W/m2 *

* Power depends on the voltage applied

ClayTec clay plaster mortar

Bonding and incorporation Heating medium: Clay adhesive and reinforcing mortar

Reinforcement layer: Clay adhesive and reinforcing mortar, flax fabric or glass fabric

Finish: YOSIMA clay designer plaster or

Clay topcoat plaster fine 06 and primer WHITE and CLAYFIX clay paint or

Clay topcoat plaster fine 06 and clay paint ready to use

Application of clay plaster

After the heating membrane bonding has dried, the reinforcing layer is applied, which again consists of clay adhesive and reinforcing mortar. The reinforcing mesh is worked into this still wet layer, the sheets must be installed with at least 100 mm overlap, the mesh must be generously continued on unheated plaster areas. After the reinforcement layer has dried, apply the clay finish of your choice.