Lehmbau Breidenbach

After graduating from high school, Peter Breidenbach was not drawn to study, but to practice. At the beginning of the 1980s, many people were already willing to authentically renovate half-timbered houses and try out alternative construction methods for new buildings. In the process, attention was repeatedly drawn to clay as a building material. However, there was a lack of logistical, mechanical and personnel infrastructure. This was the gap in the market. So, at the age of 21, Peter Breidenbach founded the construction company Lehmbau Breidenbach and took on his first major building contract. The issue of craft law was clarified with the support of friends from the heritage conservation, cultural and university sectors. In 1985, the company was entered in the register of craftsmen at the Düsseldorf Chamber of Crafts, the first company ever to be active in earth building in Germany. Right from the start, Lehmbau Breidenbach had its own specially designed machines. They had to be newly developed. There had never been a mechanized modern earth building before. Suitable employees also had to be found. These included Ulrich Röhlen, who had meanwhile started studying architecture in Aachen.

How everything started

The businessman

The history of ClayTec began in the 1970s. Peter Breidenbach comes from a family of architects with a strong connection to the traditional building trade. His parents worked primarily in the field of heritage conservation, and in 1975 they began privately restoring a half-timbered farmhouse dating back to 1661. At that time, building with natural building materials, which were also suitable for listed buildings, was not yet the order of the day. The era of unrestricted faith in progress continued. After 1945, the construction industry had experienced a profound surge in industrialization. Building methods based on craftsmanship were ridiculed. From the perspective of half-timbered house renovation, however, traditional building materials in no way appeared to be backward. In 1978, the first attempts to process clay for infill and plastering began at the Tho Rieth Hof in Viersen. The first experiences in clay construction date back to this time. Peter Breidenbach was 15 years old, his school friend Ulrich Röhlen a few years older.

The years in the building trade

As building contracts in the 1980s were still spread across the whole of Germany, clay construction meant working away from home. Monument renovations were mainly located in the low mountain ranges with their distinctive half-timbered culture. When it came to new buildings, the location was determined by pioneering builders. Over time, those earth building methods that were suitable for the building tasks of the present crystallized from the multitude of possibilities. In half-timbered construction, traditional infill methods were supplemented by clay block masonry. Lightweight loam was used for interior insulation in old buildings and as an exterior wall filling for timber frames in new buildings. It became clear that earth was less in demand for the shell of new buildings than for finishing. Clay plaster became the most important area of application, with more and more builders being won over by its climatic and visual appeal, and mixing took place on the building site for both practical and idealistic reasons. However, this came at the cost of great organizational effort: clay, sand and straw had to be available on site in the right quantities, as well as a strong water and electricity supply, and the company was involved in the renovation of important half-timbered town houses. One outstanding example is the Römer 2-4-6 house in Limburg, built in 1289. At the time of its renovation, it was considered the oldest half-timbered house in Germany. Among the new construction projects, the Ökosoziale Siedlung in Cologne-Chorweiler, an ensemble of 18 large timber-framed buildings, is noteworthy.

1978

Tho Rieth-Hof. The Beginning.

In 1975, the parents of company founder Peter Breidenbach acquired a half-timbered house from the 16th century, the Tho-Rieth-Hof in Viersen. Here, almost all earth building techniques are developed on their own building project.

1984

Company foundation

Peter Breidenbach founded Lehmbau Breidenbach on April 1, 1984, directly after graduating from high school. The first equipment for producing clay mixtures is quickly developed.

1985

Entry in the register of craftsmen

On April 22, 1985, Peter Breidenbach becomes the first clay builder in Germany to be entered in the register of craftsmen. The application was supported by numerous monument authorities.

1985

Mechanization of clay plaster processing

Clay and straw are not raw materials that can be processed with standard construction equipment, so a high-performance industrial mixer from Eirich is mounted on a trailer construction.

1986

Technology makes its entrance

Modern technology gradually finds its way into clay construction. The first plaster pump is converted so that clay plasters can also be sprayed.

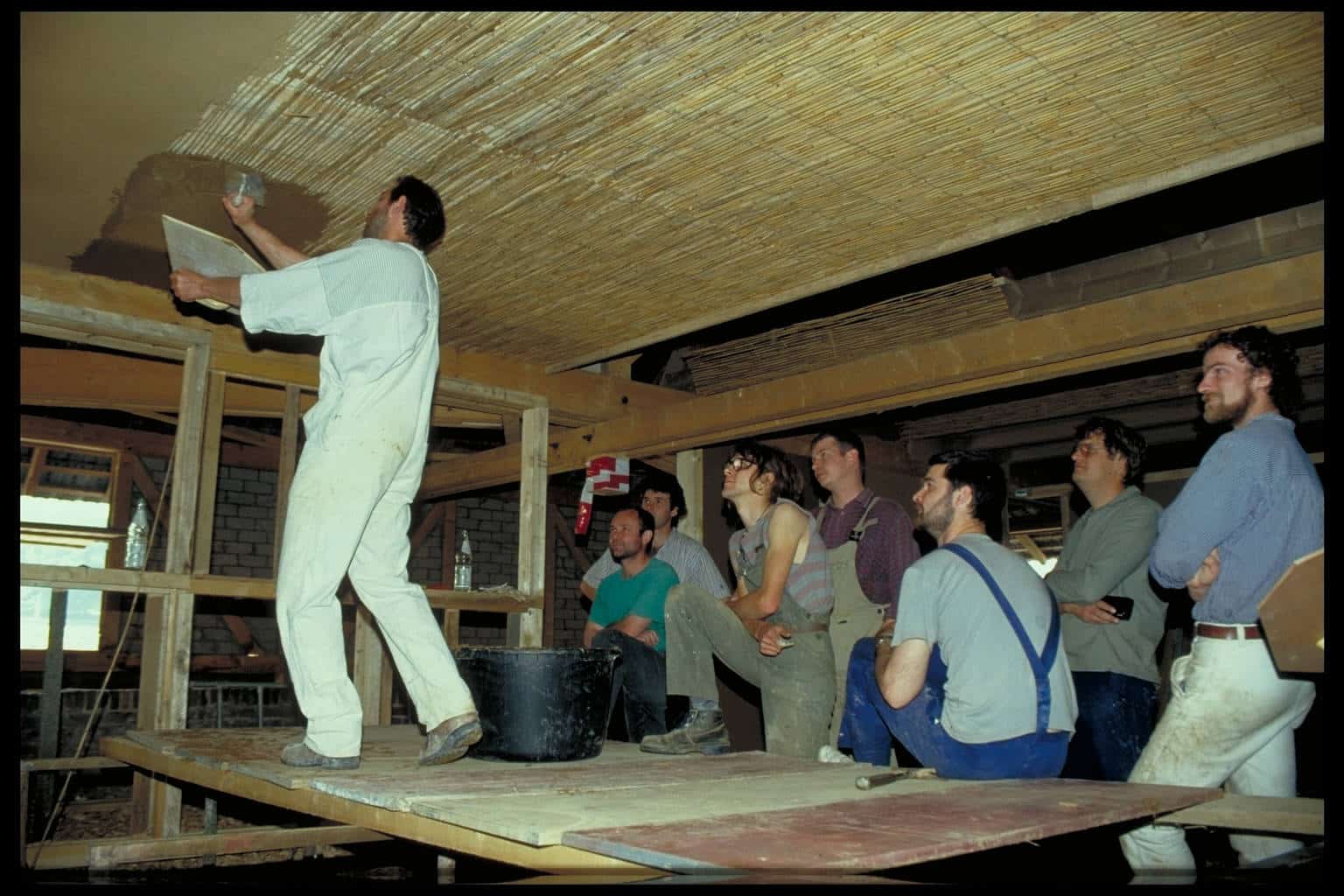

1984 - 1991

The construction site years

In the years that followed, the company grew continuously. With up to 30 employees, in up to 5 columns, Lehmbau-Breidenbach is on the road throughout Germany.

1990

Building material production

The central production of earth building materials is launched and experiments begin again with machines and systems that were actually designed for other purposes. The first production plant for earth building materials is gradually built.

1990

The Ring oven

In Viersen, the restoration of the old ring kiln brickworks is completed by the town under the direction of architect Inge Breidenbach. Lehmbau Breidenbach initially moves in as a tenant.

1992

The Trademark

Clay building materials are sold to the trade, craftsmen and end customers under the registered trademark ClayTec.

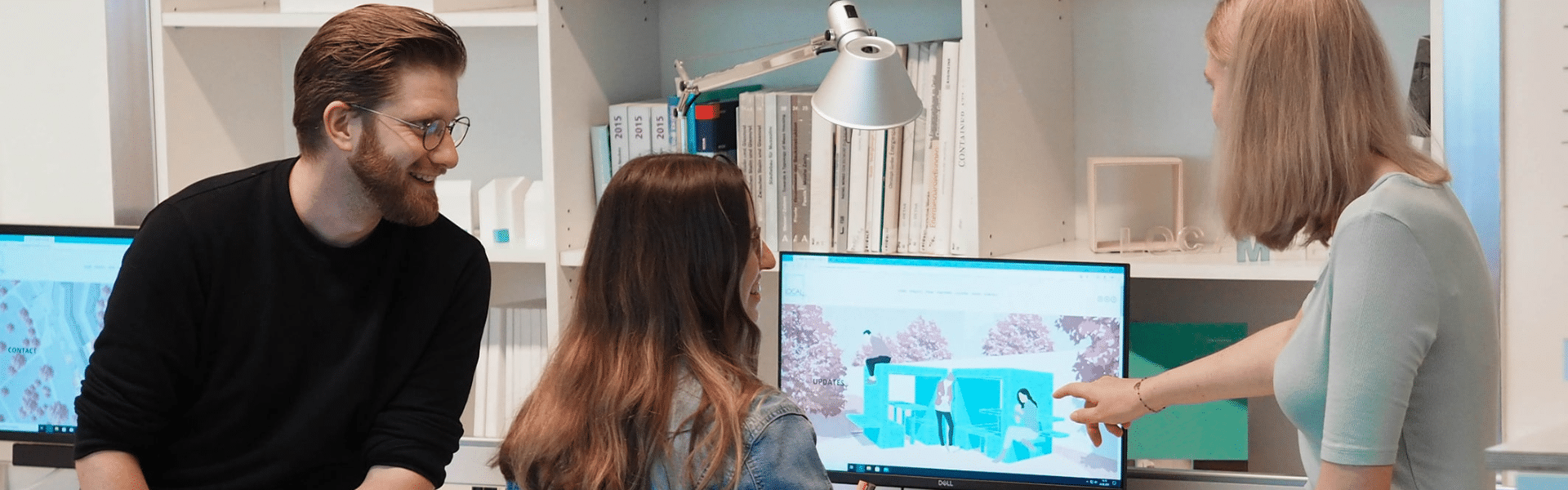

1993

Training Courses

Training courses are held on the company premises so that our customers do not have to find their own solutions. These events will be expanded in the coming years.

1996

The new office

In this year, the office moves into its own building. In the following years, two adjoining buildings are added.

1996

The clay building board

The clay building board is a milestone in the development of modern clay building materials. Clay building has finally arrived in drywall construction, opening up new building applications.

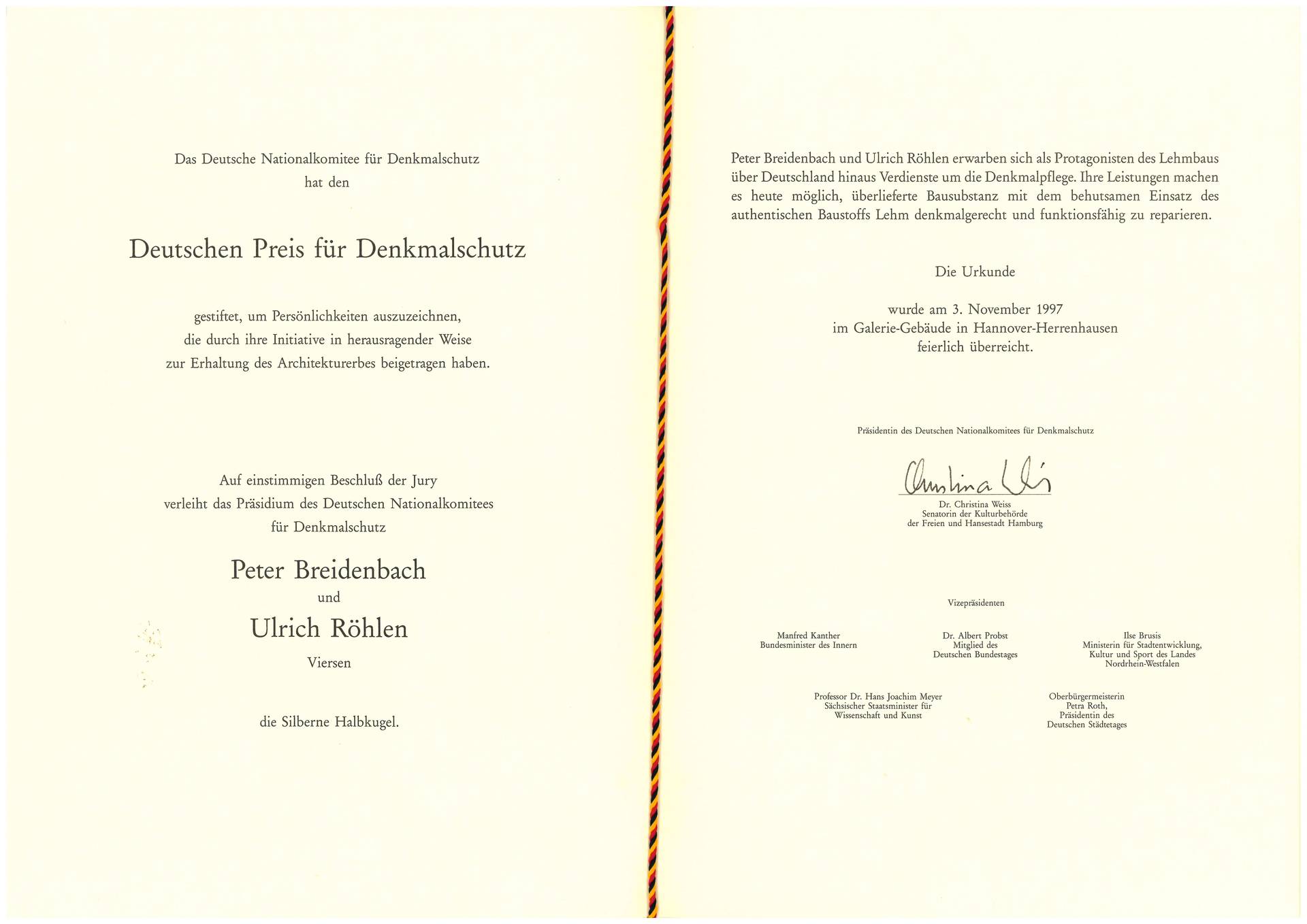

1997

The monument award

Thanks to the work of the company Lehmbau Peter Breidenbach, the historic material clay has been made usable again for craftsmanship in the preservation of historical monuments. This work has been recognized by the German National Committee for Monument Protection.

2000

The trade structure

The decision is made to offer ClayTec clay building materials exclusively through specialist builders’ merchants. The trade continues to be closely involved through partnerships.

2000

The expansion

Production is getting too cramped. A new hall is built for the production and storage of ClayTec clay building materials.

2008

The new production plant

The old, slowly growing production plant reaches the limits of its capacity. A completely new production plant is designed and built. This incorporates all the experience gained in previous years.

2009

The Kolumba Museum

ClayTec clay building materials are used in the Kolumba Museum in Cologne on several thousand square meters and demonstrate that the old material clay is ideally suited for aesthetically high-quality surfaces.

2009

The branch in the Westerwald

The Koblenz branch is opened close to important raw material deposits in the Westerwald and due to its convenient location. The move to the current location in Ransbach-Baumbach takes place in 2012.

2010

YOSIMA

The YOSIMA product line will be presented at FARBE in Munich in 2010 as the successor to CLAYFIX fine clay plaster and textured plaster. A unique color system!

2011

The branch Egeln

The branch office in Egeln near Magdeburg is founded to relieve the burden on production in Viersen and Ransbach-Baumbach and to better reach the eastern German states.

2013

The clay dry mortar production plant

A production plant for dry clay mortar is built in Ransbach-Baumbach. The range of ClayTec clay plasters is expanded.

2015

The next generation

The next generation joins the family business. After studying business administration, son Maximilian takes over the logistics, international and IT departments. In 2016, he becomes Managing Director of ClayTec Lehmbaustoffe

2020

The takeover of Cellco

As a manufacturer and producer of building materials made from clay, we have taken over the long-established company Cellco GmbH (formerly Haacke Cellco) from ClayTec. With the takeover of Cellco as a manufacturer of insulating materials made of cork and clay, we at ClayTec are getting involved where the company history of our Viersen-based family business once began: in the restoration of timber-framed buildings. The strong connection to traditional building craftsmanship still characterizes the company today – so Cellco fits in well with one of our specialist areas at ClayTec.

2020

Clay live experience: now with CLAYTOURS

Experience clay; we at ClayTec make this possible with our CLAYTOURS platform. CLAYTOURS offers a hand-picked collection of architectural objects in which clay has been used in a wide variety of building materials. Our aim is to present publicly accessible buildings such as restaurants, wineries or hotels in which ClayTec products have been used and thus offer a platform where interested parties can find objects in which they can experience and touch clay building materials and surfaces.

2021

Company expansion near to nature

The ground-breaking ceremony for the natural expansion of our company premises in Viersen is complete. In June 2021, the long-awaited expansion of the plant at the historic production site, the so-called ring kiln, on Süchtelner Straße began. The first step is the archaeological investigation of the site, as it adjoins a historic Roman road. After around five months, the new exit is finally open to traffic.

2021

New production site in the south of Germany

Shortly before the turn of the year, Peter Breidenbach, founder and Managing Director of ClayTec, announces some good news: the family business is expanding to Bächingen, in the Swabian district of Dillingen an der Donau in southern Germany, where it is opening another production site. The new ClayTec branch will be used for the production of earth-moist clay plasters and for logistical tasks.

2022

Foundation Industrieverband Lehmbaustoffe

The Clay Building Materials Industry Association was founded in Berlin in mid-November. The founding members, the companies ClayTec, Hart Keramik and Lehmorange, have set themselves the goal of representing the interests of the medium-sized clay building materials industry, promoting technical developments in unfired clay building materials and their production and supporting the process of building authority approvals. Maximilian Breidenbach, authorized signatory at ClayTec GmbH & Co. KG, was appointed chairman of the board.

2023

Simon Breidenbach takes over Sales Management